Honda K20A vs F20C

“When I started making motorcycles, the prophets of doom came to discourage me. ‘You’d be better off opening another garage and you’ll make a lot of money. I didn’t listen to them, and despite their pessimistic advice I created, on the 24th of September, 1948, the Honda Motor Company.”

– Soichiro Honda

50 years of race wins, technological innovation and sheer audacity culminated in the release of the Honda S2000. It was a no compromise sports car with a key development target - genuine driving pleasure. The spiritual significance of this car to the company could not be understated, and the best engineers in the company built the F20C engine, the beating heart of a legend. There were four key development targets for the engine:

1. High engine speeds and output power of 120HP/Liter

2. Compliance with National LEV Emissions Standards

3. Compact in size and light in weight

4. A high degree of engine response

There has been much written about why that engine is special, and since you are reading this article, you've probably seen it all already. This piece is really exploring the evolution of the F20C into the later K20A. The era of high revving, normally aspirated four cylinders ended with the Honda Civic Type R (FD2R) in 2011. Today, the K20 engine has become a popular power-plant due to its wide availability, low cost, light weight and endless aftermarket support. In the development of the F20C, a development mule was created using the Honda Prelude's H22A engine, and it will pop up from time to time in this article.

For now, let's explore this overview comparison of the two engines.

Honda took much of what they learned on the F-series and applied it where they could in developing the K-series. Unlike the F20C engine that was exclusively in the S2000 AP1, there were many different variants of the K20 engine created. Since the K20A was designed for significantly greater production numbers, while there were improvements in technology, there was also differences in processes and materials as the engine evolved. For the purpose of this article, the one I will be using as a benchmark was released in the JDM FD2R Honda Civic Type R, which had the RRC intake manifold and 11.7:1 Compression Ratio.

Starting from the engine block itself, the F20C cylinder walls had a fiber reinforced metal liner to reduce weight, improve heat transfer and reduce cylinder wear. It also has the addition benefit of reducing temperature in the area in between adjacent bores. The one major downside to this is that the F20C cannot be rebored without damaging this liner. The crankshaft in the F20C is made of forged high carbon steel (JIS:S48C) with manganese. This is heat-treated and carburized along with the connecting rods The oil feed path at the pin is chamfered by 20 degrees to ease the stress concentration and helps improve durability.

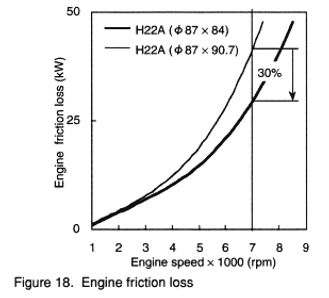

The crank stroke of the F20C is 84mm vs the K20A's 86mm. Looking at the graph below, we can see that the H22 development engine showed an exponential increase of engine friction loss as the RPMs increase when comparing the different crank strokes.

The F20C had high-strength, forged-aluminium pistons (87mm), where the K20 pistons (86mm) are high-pressure die cast construction. While the K20 pistons were around 40grams lighter, the F20C piston also included an additional oil return path underneath that helps promotes cooling (up to 10 degrees celsius) by using residual oil scraped off by the piston ring. As far as I could tell, I could not find the same feature on the K20A piston.

The K20 piston skirt was made lighter to lessen the inertial mass. Since lightening the piston causes the “neck” to rock back and forth, a molybdenum coating (also used in the NSX) was applied to lessen friction. Derek Stevens of Hondata & Joe McCarthy from Prototype Racing have noted that under extended use above 8000rpm, K20 engines have issues with piston failure.

The F20C's superior oiling system allows for more reliability for the engine overall. To help minimize engine length, Honda engineers placed the oil pump at the bottom of the engine block instead of its usual location at the front of the crankshaft. Oil is scavenged more efficently and the engine more compact. The high-speed rotor and suction-pickup ports on both sides of the pump body supplies a greater volume of oil to the engine at all engine speeds. While there have been anecdotal reports that the K20 experiences oil cavitation at around 8,300rpm, oil pressure in the F20 has no such issue until 9,500rpm.

Moving on to the cylinder head, the F20C utilized "dummy head honing," a process where the engine block cylinders are honed with a simulated cylinder head part tightened to the block, which improved machining accuracy to aid the stability of piston movement. It is likely that the K20A did not use this process due to the higher volumes of engines produced.

The F20C head benefits from slightly larger valves (+1mm), a slightly narrower port angle (+1 deg) as well as slightly higher lift cams. All of these add up to around a 5-8% increase in stock headflow. However, over the last decade, development of the K20 cylinder head by different aftermarket companies have started to unlock the potential that the Honda engineers gifted us.

In an interview with Super Street Magazine, the owner of 4 Piston Racing Luke Wilson notes that his team developed a billet block CNC cylinder head to specifically increase power beyond 11,000 rpm. He notes that OEM Honda castings offer sufficient performance for smaller-displacement endurance and drag race engines.

The S2000 intake manifold was designed primarily to maximise throttle response. The volume of the manifold was relatively reduced compared to conventional wisdom. Using the development mule engine, the Honda H22A, they noted that this decision reduced the time it took for the throttle to respond by 30% at 7,000rpm. At 9,000rpm that number increases to 42% which means there will be less undesired revving of the engine while changing gears. The RRC manifold in the K20 likely has a larger plenum volume, although I could not find evidence to support this.

Both the F20C and K20A have VTEC (Variable Valve Timing & Lift Electronic Control) which allows an engine to alternate between two different camshaft profiles at different engine speeds. The standout difference of the two engines is that the K20A has VTC (Variable Timing Control) on the intake camshaft. This allows the camshaft to be infinitely variable, so that the overlap between the intake and exhaust camshafts can be varied throughout the RPM range optimising the efficiency of the engine. Called iVTEC, this combination of VTEC with VTC makes the K20A more responsive and have more torque at lower RPMs. It's important to note that the F20C and the K20A would likely have comparable peak power if built to the same standard, however, in terms of drivability at lower RPM's the K20A will have the advantage.

The graph above was created to mimic Honda's own dyno sheets published at the launch of the S2000 and the FD2R. It's important to note that the K20A's camshaft duration is not as aggressive as the F20C, and that is why we see torque peak earlier for that engine. For the same displacement, the K20A produced 5-12% more torque at a given RPM. It get betters fuel economy and emits less emissions as well.

There have been plenty of flame wars that have erupted over which is the better engine. What constitutes better depends on the application, and on paper, the F20C seems like the better platform for peak power, while the K20A might be a better choice for a street car that lives at lower RPMs. However this ignores the fact that the F20C was designed for a limited production sports car, and the other to power almost the entire range of the brand.

Twenty years since the F20C debuted, and after millions of K20A engines have now been produced, these engines hold a special place in the heart of any petrolhead, and the passion that led to their existence continues in the continued development for these platforms by those who believe in the power of dreams.

Sources:

http://www.superstreetonline.com/how-to/engine/1904-4-pistons-k-series-billet-cylinder-head/

https://www.honda.co.jp/factbook/auto/CIVIC_TYPE_R/200703/04.html

https://www.honda.co.jp/factbook/auto/s2000/199904/

Development of the High-Power, Low-Emission Engine for the “Honda S2000”

DOI: https://doi.org/10.4271/2000-01-0670

Author(s): Yutaka Otobe, Hiroshi Kawaguchi, Hideo Ueshima